Insight: Behind the Scenes at Honda Performance Development

HPD President David Salters takes Sportscar365 on an unrivaled tour of Honda, Acura's North American motorsports headquarters...

"We're all crazy motorsport people."

That’s how David Salters describes Honda Performance Development, the North American motorsports arm for Honda and Acura that’s been responsible for the brands’ success in various forms of the sport over the last 30 years.

From 15 victories in the Indianapolis 500 to multiple class wins at the 24 Hours of Le Mans, numerous IMSA and IndyCar titles, as well as most recently becoming the first LMDh manufacturer to win in IMSA’s new GTP class, HPD has been one of the key players in modern day motorsports, yet has sometimes stealthy flown under the radar.

Salters, who has served as the company’s president and technical director since 2020, took Sportscar365 on a tour of HPD’s sprawling 123,000 square-foot facility in the build-up to last month’s Acura Grand Prix of Long Beach, in an unprecedented behind-the-scenes look at the championship-winning organization.

Founded in 1993, HPD’s original 43,500-square-foot space in Santa Clarita, Calif. was designed to primarily serve as an engine rebuilding facility. Having outgrown its space, the company moved a few miles away to a dedicated new headquarters in 2005 that was designed from the ground-up to serve as an advanced R&D and manufacturing facility.

The multi-story building was abuzz during our tour, with the final touches being put on the Honda twin-turbo V6 powerplants for the Indy 500. HPD differentiates the engines built by having red covers for Honda and blue for Acura while inside its prep room, which featured dozens of assembly bays for various projects.

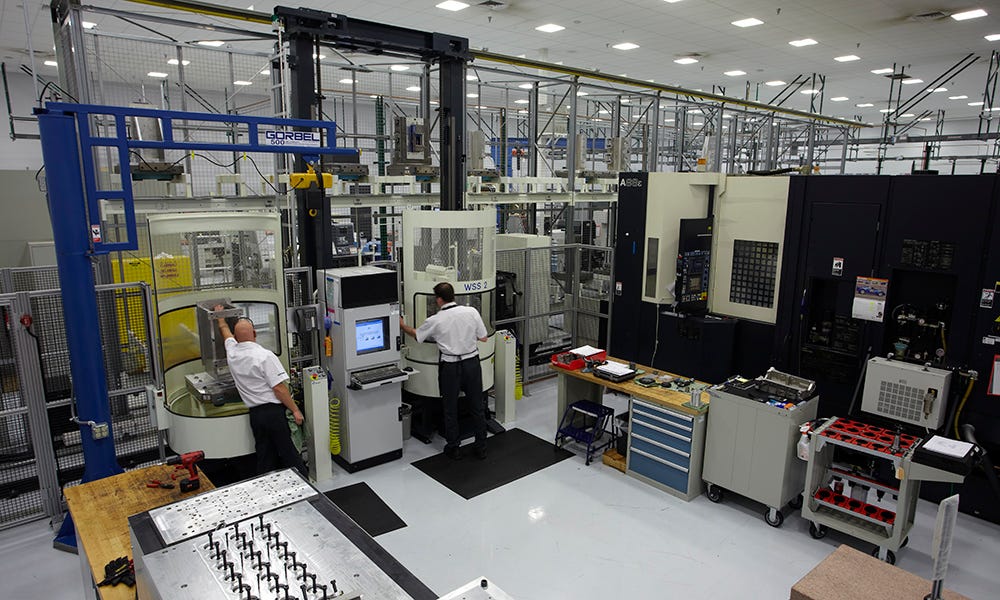

Next door, workers were in a morning meeting in the fabrication room, which houses state-of-the-art equipment to prototype and built parts.

While not having the capability to manufacture every engine component in volume, such as crankshafts, Salters explained that it designs and creates prototype parts that are then outsourced to suppliers around the world.

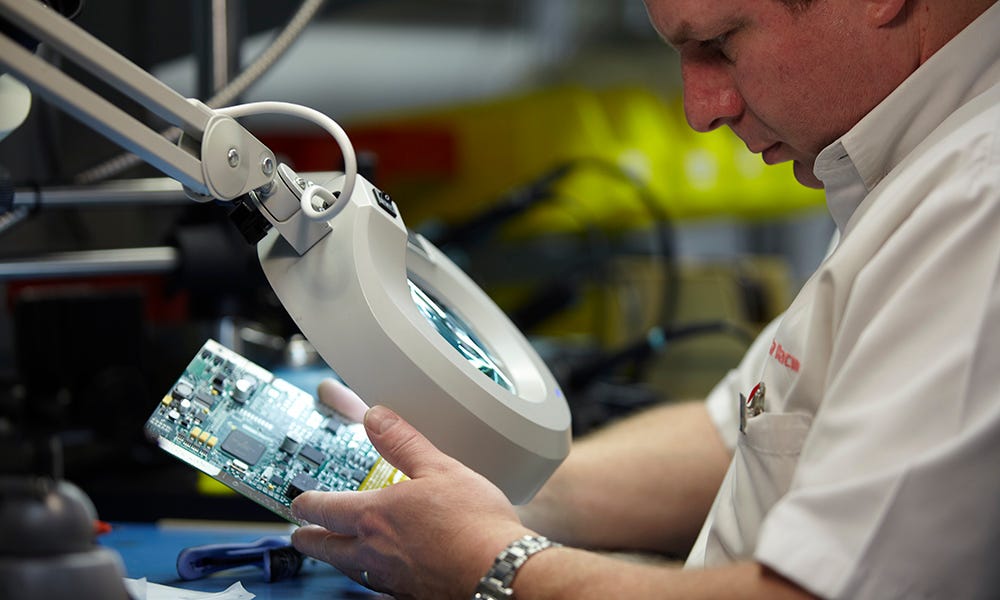

The materials lab, meanwhile, is used for in-house analysis on metallurgy and other components to diagnose failures, enforce quality control standards and to even detect counterfeit materials, which Salters says has occurred from suppliers in previous isolated incidents.

Quite arguably the most impressive part of HPD’s facility is the dyno room, which is typically used for 12 hours a day, seven days a week. Engines are prepped and dressed in a separate room before being moved in one of six cells, including dedicated single cell and transient dynos.

There is room to expand the dyno block for an additional two cells in the future, a HPD spokesperson said.

In the single cell dyno, where external oil, fuel and water lines are utilized, HPD engineers were working on oil dilution with the 2.4-liter twin-turbo V6 engine that’s used in the Acura ARX-06 LMDh car.

Meanwhile, the next-gen IndyCar engine was running in a specially equipped high-voltage dyno cell that can test a motor generator unit with a battery simulator.

HPD has equipped the facility with a number of ‘HV restricted’ rooms, including one in its electrical lab that housed a previous-generation Honda Formula 1 battery. Salters explained they work alongside Honda Racing Corporation in Japan for a number of projects and have benefited from having technology transfers between the two Honda motorsport-focused companies.

In addition to dedicated engineering and development/design offices, the one element that stood out was that Salters, as well as HPD Vice President Kelvin Fu’s office cubicles were on the ground floor mixed in with the rest of the staff. Honda and Acura Motorsports manager Chuck Schifsky explained that this is a “Honda-influenced” design, similar to other Honda offices around the world.

A 3D-printed tub of the Acura ARX-06, meanwhile, was on the main office floor, which Salters explained was used for initial seat fitting and cockpit design with Ricky Taylor. Nearby, there was a hardware-in-the-loop simulator, fitted with a LMDh ECU and steering wheel that can run in real-time.

Upstairs, HPD has built its own ‘mission control’ room for the Acura GTP project. Much like other manufacturers, “SC3”, which stands for Santa Clarita 3, offers a remote link to race tracks as well as HPD’s driver-in-the-loop simulator located near Indianapolis, for additional engineering support.

Wayne Taylor Racing with Andretti Autosport’s Filipe Albuquerque was in the DIL at the time of our tour preparing for Long Beach, with HPD vehicle dynamics engineer, and part-time driver, Matt McMurry, working with Albuquerque while in an office in Santa Clarita.

In addition to housing the DIL, HPD’s secondary facility, dubbed ‘HPD-I’ in Brownsburg, Ind., is also used for remote servicing and parts storage for both the IndyCar and sports car programs.

HPD has also been ramping up its capabilities of building complete race cars in-house, with the prototype models of the Honda TC and TCA Civics having been produced at its headquarters, as well as housing several one-off projects including the popular Honda CR-V Hybrid Racer and Acura’s all-electric NSX Pikes Peak car.

While being involved with a number of projects, including the Honda Baja Ridgeline off-road trucks, which utilizes the same 3.5-liter V6 engine from the Acura ARX-05 DPi car, Salters said the common link through it all are the people that work behind the scenes.

Of note, all HPD employees carry Honda badges and are technically employed through American Honda. HPD, meanwhile, is an independent entity of Honda Motor Co. Ltd. in Japan.

"Our goal is to promote Honda and Acura but actually our goal is to develop people [and] technology,” Salters says. “It's not BS, you can see there's real people doing real stuff. It's not rocket science. It's getting the right people in the right places, bringing energy in and going in the right direction.

"If you've got your team working together going in the right direction you'll achieve a lot. It's about the people, all of the other stuff is fluff. You need resources with the right stuff and you need people that are going to support you. But it all comes down to the people.”

HPD has seen a gradual increase in staff, growing from 150 to nearly 250 in recent years through the build up of the factory GTP program and next-generation IndyCar engine, which ran alongside its then-existing IMSA DPi effort and current IndyCar operation.

As for what could be next, Salters said that’s up for discussion between HPD and American Honda Motor Co.

"We have quarterly marketing meetings and we constantly review what we're doing, is it working? Where are we going?,” he says. "We also have a high level supervisory board -- a race steering committee - which is basically the VP of sales, VP of marketing, VP of C.A.S.E (Connected, Autonomous, Shared and Electrified) and VP of Acura.

"We have the top level of American Honda and we will meet at a similar cadence and that's more strategic. With marketing people, we'll look a year or two out. And we also talk about five years or ten years. What will be happening in five years?

"We also have an advisory board that's invaluable to me. Where is Honda going? Where is Acura going? What do we need in five years' time? We do it on a quarterly basis, which is not easy at the moment because the world is turned upside down.

"I think GTP has been a great step forward. Those cars look like the future. They've got a personality, they look cool, they sound cool, we've got the electrification. It's still hugely entertaining. The racing is amazing. So that's great. But it's after that, we're trying to figure that bit out."

Photos: HPD, Mike Levitt

good reporting. what about lemans for Acura?